What Does A Surfacing Router Bit Do?

Surface forming router bits are powerful tools in the world of woodworking that offer a range of benefits and applications. Whether you're a professional craftsman or a DIY enthusiast, understanding what a surfacing router bit does can revolutionize the way you work with wood. In this article, we will explore the capabilities and functions of surfacing router bits, unveiling their potential to transform rough lumber into smooth and pristine surfaces.

Understanding Surfacing Router Bits

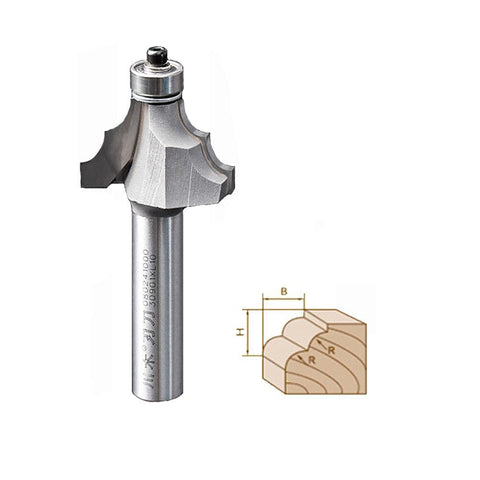

Surfacing router bits, also known as planing or flattening bits, are designed to level, flatten, and smooth large surfaces of wood. These bits feature multiple cutting edges and are typically larger in diameter compared to other router bits. They are commonly used with handheld or CNC routers to remove material from the surface of the wood, resulting in a flat and even finish.

Applications of Surfacing Router Bits

Surfacing router bits find extensive use in a variety of woodworking applications. Here are some of the key applications where these bits excel:

- Thickness Planing: One of the primary applications of surfacing router bits is thickness planing. These bits are highly effective in leveling and removing excess material from rough lumber, allowing woodworkers to achieve consistent thickness across the entire workpiece. By using surfacing router bits, you can transform irregular and uneven boards into smooth and uniform pieces ready for further woodworking processes.

- Slab Flattening: Surfacing router bits are invaluable for flattening large slabs of wood, such as those used in tabletops, countertops, or other furniture pieces. Slabs often contain imperfections, such as twists, cupping, or uneven surfaces. With the use of surfacing router bits, these imperfections can be effectively removed, resulting in a flat and stunning surface that showcases the natural beauty of the wood.

- Resurfacing and Restoration: Surfacing router bits are also useful for resurfacing and restoring old or damaged wooden surfaces. Whether it's an antique piece of furniture or a worn-out tabletop, these bits can remove layers of old finish, stains, or damage, revealing a fresh layer of wood underneath. By resurfacing with a surfacing router bit, you can breathe new life into worn-out pieces and restore their original beauty.

Advantages of Surfacing Router Bits

Using surfacing router bits offers a range of advantages for woodworkers:

- Efficiency: Surfacing router bits are designed to remove material quickly and efficiently, saving time and effort. The larger diameter and multiple cutting edges allow for more substantial material removal in a single pass, speeding up the surfacing process.

- Precision: Surfacing router bits enable precise material removal, resulting in flat and even surfaces. This level of precision is crucial for achieving seamless joinery, creating perfectly fitting panels, or ensuring uniform thickness across multiple workpieces.

- Versatility: Surfacing router bits can be used with handheld routers or CNC machines, offering versatility in terms of workpiece size and complexity. From small-scale projects to large slabs, these bits can handle a wide range of woodworking tasks.

Tips for Using Surfacing Router Bits

To make the most of surfacing router bits, consider the following tips:

- Router Stability: Ensure your router is securely mounted or held in place to prevent movement during the surfacing process. Stability is crucial to achieve consistent and accurate results.

- Multiple Passes: Depending on the thickness of the material and the desired surface finish, it may be necessary to make multiple passes with the surfacing router bit. Gradually increase the depth of cut with each pass to achieve the desired result without straining the router or causing tear-out.

- Safety Precautions: Always prioritize safety when working with surfacing router bits. Wear appropriate protective gear, such as safety glasses and dust masks, and follow proper safety procedures to prevent accidents and injuries.

Conclusion

Surfacing router bits are indispensable tools for achieving flat, smooth, and pristine surfaces in woodworking. Whether you're thickness planing rough lumber, flattening large slabs, or restoring old wooden surfaces, these bits offer efficiency, precision, and versatility. By understanding the capabilities and applications of surfacing router bits, you can unlock their potential to transform your woodworking projects. Embrace the power of surfacing router bits and take your craftsmanship to new heights, creating flawless and stunning surfaces that truly showcase the beauty of wood.